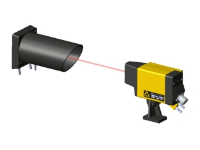

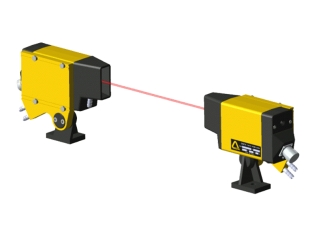

Through Beam Laser Barrier

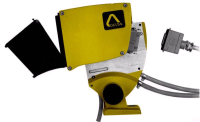

VL-VRG

- Detection of hot or cold products

- Visible laser beam

- Models with alarm signal

- Designed for harsh environment

Special Features

- Intense, highly directive, visible red laser diode beam.

- Insensitivity to ambient light.

- Adjustable sensitivity.

- A LED indicator showing operation of the receiver.

- Air purging.

- Optional water-cooling jackets for use at ambient temperatures higher than 50 °C (122 °F).

- Alarm signal when the lenses become too dirty or when the internal temperature is too high.

- Modular construction allowing rapid maintenance.

- Optional features allowing configuration for any application.

Typical applications

The Laser Barrier VL/VRG resolves all detection problems that may arise in the most diverse types of industry, for example heavy industry (steel), handling and transport, etc. It is particularly recommended for the following applications:

The emitter VL unit emits a high intensity, visible beam of modulated red laser light. This beam is received by a photosensitive diode fitted with an optical filter and whose signal is processed by the incorporated circuitry of the receiver VRG. The output changes state depending on whether the modulated beam is interrupted or not. Beam modulation, special optical filter and automatic correction make the sensor insensitive for ambient light.

Commissioning and Alignment

The visible, intense and highly directive laser beam makes the setting up of the optical barrier VL/VRGsimple and rapid.

To align the sensor, use the following procedure:

- Mount the VL emitter and adjust its orientation while at the same time observing the point of impact of the beam on the product to be detected.

- Observe the impact of the laser beam on a target near the VRG receiver.

- Position the receiver so as to center the beam on its lens.

- Set the receiver sensitivity potentiometer to maximum.

- Turn the receiver about its axis in order to find the extreme positions where the output changes state.

- Fix the receiver in the central position between these two extremes.

This procedure guarantees a precision for the detection of approx. 1 cm for a product of cross-section greater than 4 cm.

The accuracy of the detection can be increased by optimizing the detection threshold adjustment with the sensitivity potentiometer.