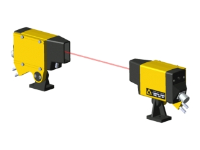

Incremental Solid Shaft Encoder

GDP-GDC

- Heavy duty Pulse Generators

- Water cooling for operation up to 120 °C

Typical applications

The main applications of the Pulse Generators GDC and GDP are positioning, length measurement and numerical tachometry on continuous casting machines and hot and cold rolling mills.

Features

The Pulse Generators GDC-GDP have been designed for heavy industry. They are extremely robust and can withstand vibration and work in difficult temperature condition.

- Rugged and reliable under most difficult environmental conditions

- Cast Aluminium housing

- Stainless steel shaft

- Water cooling version for ambient temperature up to 120 °C

- Waterproof (IP66)

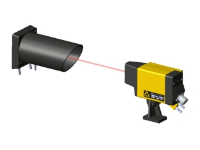

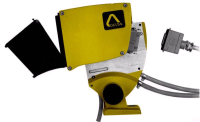

The GDC encoder has a cylindrical housing. The GDP encoder has 4 fixing feet.

The shaft is mounted with 2 large ball bearings, lubricated for life and sized for high radial and axial load. They offer a high vibration and shock resistance.

The connection of the GDC model is made with a connector, and the GDP model with terminals.

Operating Principle

A disc with radial transparent slots is scanned with an opto-electronic reading unit. The number of slots determines the resolution (pulses per turn).

Signals from each channel are processed by the built-in electronics. The output is high level pulses in complementary pairs. This enables transmission over large distances without interference even in electrically noisy environments.

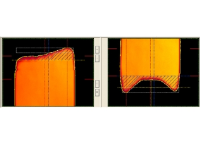

Output channels

- Single channel GDC-GDP with one output signal S1 is used when the drive only rotates in one direction or if it is not necessary to detect the direction of rotation.

- Double channel GDC-GDP with two output signals offset by 90°, S1 and S2, can detect the direction of rotation.

- Double channel GDC-GDP with a marker pulse (REF): the additional marker pulse enables counting full revolutions or counter reset.

Diagram for clockwise shaft rotation as seen from the shaft.