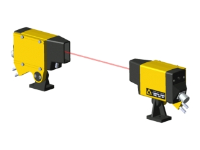

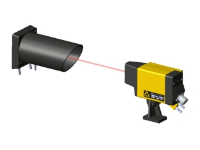

Reflecting Optical Barrier

V3

- Detection of hot or cold products

- Design for extremely harsh environment

- Visible optical barrier

Benefits

The sensor V3 works in association with a reflector R (cf. literature E 3990).

- Visible red diode emission.

- Insensitivity to ambient light.

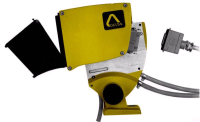

- Cast aluminium case with air purged hood for protecting the lens and with water-cooling plate.

- Modular construction allowing rapid maintenance.

- Alignment and checking devices: sensitivity potentiometer, light indicator showing operation.

- Alarm signal when lens or reflector is dirty.

Presentation

The Optical Barrier V3 consists of:

- An optical unit equipped with an emitting diode, reception photodiode, electronics with high current transistor output, relay or opto solid state relay and power supply.

- A terminal block with protection cover or a connector fitted with high temperature cable with protective steel braid.

- A hood for lens protection with air purging connection.

- An optional water-cooling plate for use at ambient temperature higher than 70 °C (160 °F).

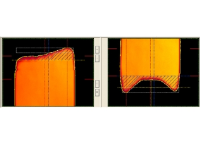

Operating principle

The visible and modulated beam emitted by the diode is reflected back by a prism reflector placed opposite to the sensor, then detected by the photodiode which outputs a signal to the processing electronics. Product presence is determined depending on whether the beam is blocked or not. Beam modulation, special optical filter and automatic correction make the sensor insensitive to ambient light.

Commissioning

- 1. Locating the path of the beam

They are two ways of locating the path of the beam:

- Under low ambient light conditions and at small distances the impact of the beam may be seen on the reflector.

- Otherwise looking from the reflector position towards the sensor and searching with the eye the position where the emitter LED is the brightest.

- 2. Mechanical orientation

Rough positioning of the sensor can be carried out by locating the path of the beam near the product to be detected and at the reflector.

- 3. Adjustment of the detection position

The detection position is adjusted using the sensitivity potentiometer.

With the sensitivity adjusted to the maximum value, the accuracy for the detection is approximately +/-1 cm for a product of cross section larger than 4 cm x 4 cm. Adjusting the sensitivity will increase the detection accuracy.