Scanning Hot Metal Detector with bargraph & laser line

ACCESSORY for ROTA-SONDE DC4500

- Smart display with Signal level

- Easy alignment with Laser Line

- Design for the most difficult applications

- Very High Sensitivity 180 °C / 360 °F

-

Presentation

The Rota-Sonde DC4500 is a scanning sensor, which is sensitive to the infrared radiation emitted by hot products.

It is a self-contained detector including: - An optoelectronic case with heavy duty connector.

- A protecting hood with air purging.

- A cooling plate with an adjustable mounting stand.

-

Thanks to its design and particularly its cast aluminium housing, the Rota-Sonde DC4500 is specially adapted for the harsh environment of the Steel Industry (shocks, vibrations, heat, vapour and dust).

Benefits

- High detection accuracy thanks to the narrow lateral field: independent of product temperature, size or position.

- Reliable detection even in the presence of steam or dust thanks to the small analysing beam.

- Easy alignment of the sensor with integrated laser line (model –LL) or laser pointer (model –LP).

- Easy setup with integrated LED bar-graphs: signal amplitude and detection thresholds.

- Extensive diagnostic features including display of alarm and low detection margin signals.

- High sensitivity: 180 °C / 360 °F.

- 2 sensitivity ranges with on line selection.

- Shutter with 2 fixed apertures: 2 mm for usual applications and 0.7 mm for high temperature applications.

- Easy maintenance: very quick access to window glass, rapid exchange of the sensor.

- Direct replacement of DELTA models Rota-Sonde DC3000 and DC4000.

- Remote setting and diagnostic with optional junction box CR4500DC, when access to sensor is not easy.

- Choice between relay output (DC45x0-xx) and static relay output (DC45x6-xx)

-

Applications

The Rota-Sonde DC4500 is a scanning hot metal detector for rolling mill and continuous caster applications, offering two sensitivity ranges, two self-monitoring functions and a display with bargraph to help setup.

The “high sensitivity” range enables detection of steel product at a temperature as low as 180 °C / 360 °F.

The Rota-Sonde DC4500 is perfectly suitable for all detection applications of low-temperature rolled product or low emissivity materials such as hafnium, aluminum... It is also convenient for applications where a change in the process or material leads to major variations in the temperature of the product or its emissivity, as after quenching, or for special steels, etc...Operating principle

Infrared Scanning for high detection accuracy:

The Rota-Sonde DC4500 scans the infrared radiation emitted

by hot products within a narrow lateral field with different angles

of 10°, 30° or 50° depending on the model..

- Wide vertical detection field angle (up to 50°);

- Narrow horizontal detection field for very accurate detection;

- Small detection spot allowing installation at large distances from the product without reducing the sensor sensitivity.

-

Large infrared spectrum for high sensitivity:

The Rota-Sonde DC4500 is designed with an infrared photocell having high sensitivity and wide spectrum wavelength range for sensing steel at temperatures as low as 150 °C (300 °F); thus allowing reliable detection at a temperature of 180 °C (360 °F).

All these features provide accurate and reliable detection, whatever the dimensions and the temperature of the product, or

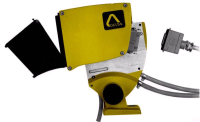

its distance and its position in the scanned field.Construction

The Rota-Sonde DC4500 is enclosed in sealed heavy duty

aluminium housing and includes: - A cooling plate with a stainless steel pipe for water cooling.

- A hood with air purging to protect the window glass. The hood is fitted with a draw latch for quick access to the window glass (DC4510 and DC4530).

- A shutter with 2 apertures 2 mm and 0.7 mm.

- A mounting stand, which permits to adjust the position of the field of detection in two axes.

- Water and air purging connections are located on the support plate. In this way it is possible to remove the sensor without disconnecting the water and air supplies and without need of optical realignment.

- A heavy duty connector, including high temperature cable with protective steel braid.

-

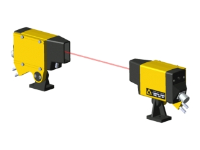

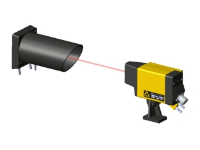

Alignment laser

The Rota-Sonde DC4500 can be supplied with two types of

laser:

- Laser Line (LL version): The laser shows the exact position

of the detection field. This makes the alignment of the

sensor in both directions easier. - Laser Pointer (LP version): a laser pointer gives the lateral

position of the field of detection. -

Extended setting and diagnostic functions

Control panel protected by a flip cover:

- Two bar-graphs: one for live level of photocell signal (green LED).

The other (blue LED) for information on threshold (THR.) setup. - Two sensitivity setting potentiometers (one for each range) with

blue LED indicating which one is active. - A LASER / TEST button: To switch On/Off the laser for alignment.

To initiate a test (press during 3 sec). This test can also be activated

remotely. - Three LED for sensor status.

-

Self-monitoring functions:

In order to optimise preventive maintenance and to improve reliability, the Rota-Sonde DC4500includes: - ALARM output and LED: this signal is activated when there is an internal failure of the sensor: Internal temperature too high (limit of 55 °C / 130 °F), scanning system or electronics board failure.

- CONTROL output and LED: this signal is activated when the detection margin is not sufficient (2 LED on the bar-graph). This is an indication that the window glass is getting dirty or that the background is becoming too hot. It is activated also in case of incorrect sensitivity setting.

- Remote test function.

-

Accessories

- Heat Shield to protect sensor from direct radiation.

-

- Junction box CR4500DC for remote settings and diagnostics.

-